Digital Product Passport and Asset Administration ShellThe future of digital product information

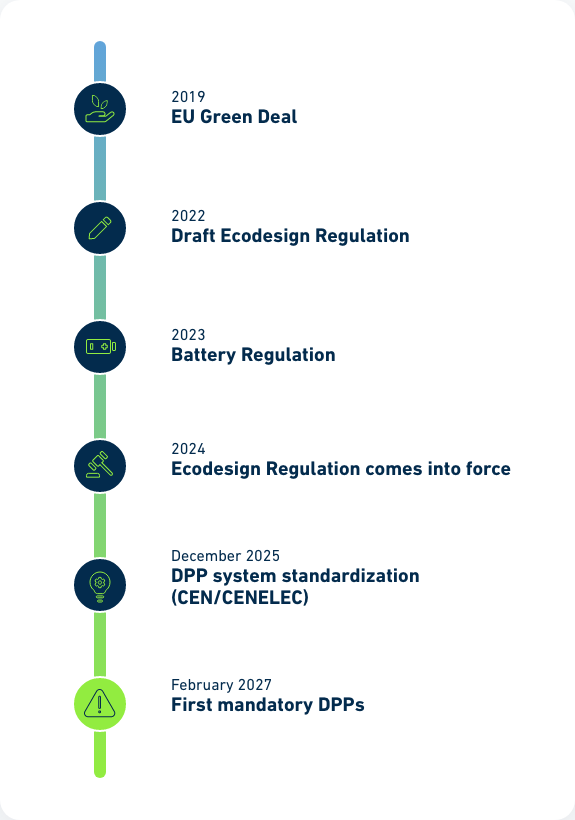

Ready for 2027The DPP is decided

You want to focus on your core competences? We support you in complying with current and future regulations to achieve an EU-wide circular economy.

The adoption of new ESG legislation presents companies with ever greater challenges when it comes to documenting process and product information.

Der EU Green Deal im Jahr 2019 und die Ökodesign-Verordnungen der letzten Jahre werden im Februar 2027 zu den ersten verpflichtenden Digitalen Produktpässen (DPP) für ausgewählte Produkte führen. Darunter Batterien, Textilien und industrielle Rohstoffe wie Eisen oder Stahl.

It is certain that further products will follow. Act now to fulfil all legal requirements for your production and supply chains in the future and benefit from the various advantages of the DPP.

Advantages and differentiationOur approach: the DPP4.0

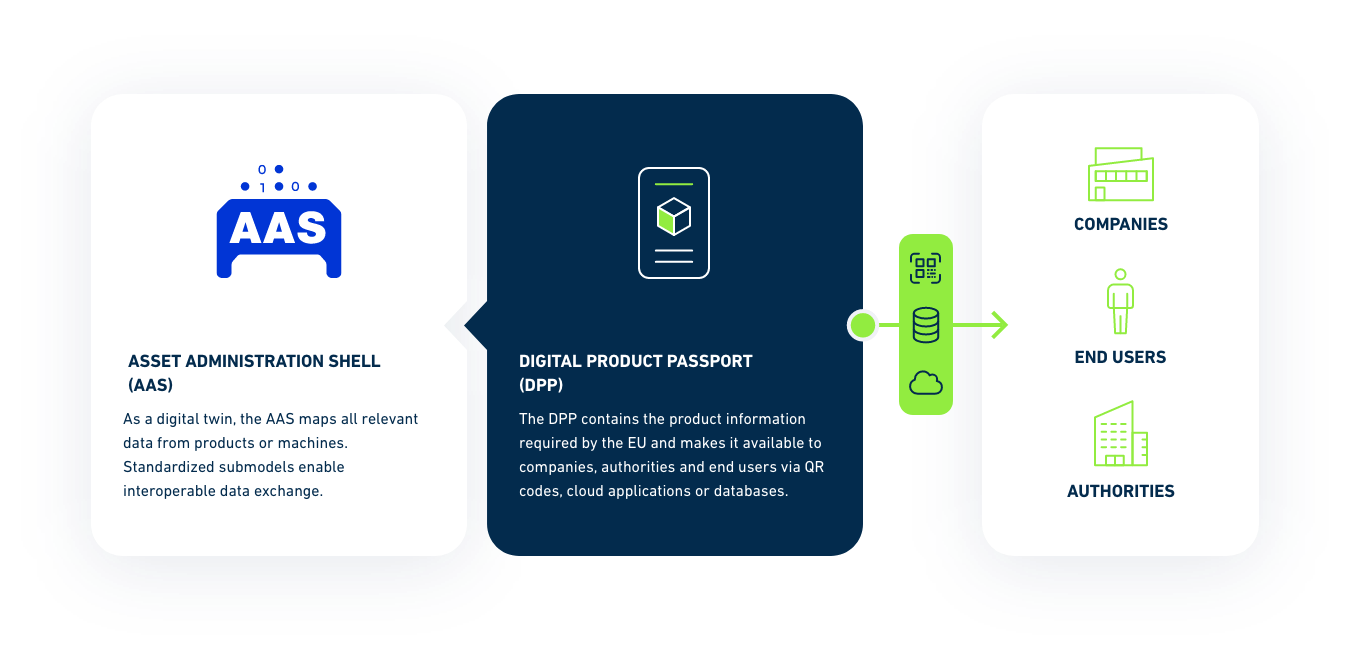

The DPP4.0 is an approach for the implementation of the DPP required by the EU, which is driven by IDTA and ZVEI, among others. The Administration Shell (AAS) and the ID Link form the basis for this approach. However, regulatory compliance is only one aspect of DPP4.0, it also enables a variety of new business models.

Overarching

standardization

The DPP4.0 ensures seamless compatibility between different systems from different institutions. This boosts your efficiency and enables consistent data processing.

Unique

identification

Thanks to universal labelling, all product information is visible at a glance and machine-readable. This makes it easier for you to trace all components and minimizes production, maintenance and usage errors throughout the entire product life cycle.

Decentralized

storage

Reduce your dependency on centralized servers and systems and ensure data protection and the constant availability of all relevant product data.

Protected

data

Access to product information is regulated via various authorization mechanisms. In addition to publicly accessible data, sensitive information can also be shared. You decide who can access which data.

More than just a data sheetWhat the digital product passport has to offer

The digital product passport provides far more than just data on sustainability factors. Stored spare parts information, operating instructions and maintenance details bring manufacturers and their customers enormous efficiency gains in product utilization.

Tomorrow's product and device documentation.

-

Trace a product’s supply chain at the touch of a button

-

Easily read out product properties, operating instructions and maintenance intervals

-

Check recyclability in a matter of seconds

Examples from industryWhat DPP and AAS mean in practice

Cross-sector application, efficiency

gains and transparency for all.

Raw material passport for houses:

A building can receive a digital product passport for all building materials used to facilitate later dismantling and recycling.

Deception-free

property purchases:

property buyers can read about all the materials used, renovations and changes to the building fabric of houses in the DPP.

Life cycle management

of buildings:

AAS enables data on maintenance, energy consumption and material quality to be documented over a period of years.

Proof of origin of materials:

Customers can use a QR code or NFC chip to see whether a jacket is made from organic cotton or recycled plastics and where the materials come from.

Second-hand:

The DPP contains repair instructions or indicates whether a product is suitable for resale.

Traceability of raw materials:

Manufacturers must use the DPP to prove whether raw materials come from sustainable sources.

Extending product life:

Consumers can use the DPP to see whether spare parts are available for their smartphone or laptop.

Recycling & Circular economy:

An electronics manufacturer can use the DPP to guarantee that its product is recyclable and which materials can be recycled. This enables consumers to make more conscious purchasing decisions.

Predictive maintenance:

Manufacturers can use the AAS to analyze machine data and identify maintenance requirements at an early stage in order to avoid potential breakdowns.

Proof of sustainability for industrial plants:

A machine manufacturer can use the DPP to prove that its products are energy-efficient and recyclable – a real advantage over its competitors.

Trace the life cycle of a component:

A company can use the DPP to determine whether a component needs to be recycled, repaired or replaced.

E-car batteries:

The EU is planning mandatory labelling for batteries with information on the origin of the raw materials, carbon footprint, service life and recyclability. The DPP enables transparent tracking along the entire supply chain.

Spare parts management:

Workshops can use the DPP to recognize which parts of a vehicle can be replaced or repaired in order to extend the lifetime of the vehicle.

CO₂ tracking for sustainable mobility:

Manufacturers can document CO₂ data for each vehicle to prove compliance with environmental regulations.

The foundation for the DPP4.0The Asset Administration Shell

As a standardized ‘Verwaltungsschale’, the AAS contains all the relevant data for a product or machine.

Your partner for the digital twinWe implement the

DPP for you

With Codewerk as your Industry 4.0 partner at your side,

you benefit from the following advantages:

- Comply with legal obligations to provide evidence without additional effort

- Improved interoperability

- The provision of standardized data formats

- Competitive advantages through transparent and truthful product information

- More efficient processes in production and further processing for you and your customers

REFERENCESOUR SOFTWARE DEVELOPMENTS –

SELECTED EXAMPLES

We’ll be happy to provide you with insights into other projects any time. Just contact us!

Model-based software engineering for the vehicle control unit

GETTING THERE FASTER

We speed up the development and validation of vehicle control software using model-based software engineering.

DEVELOPMENT OF IOT AND EDGE APPLICATIONS

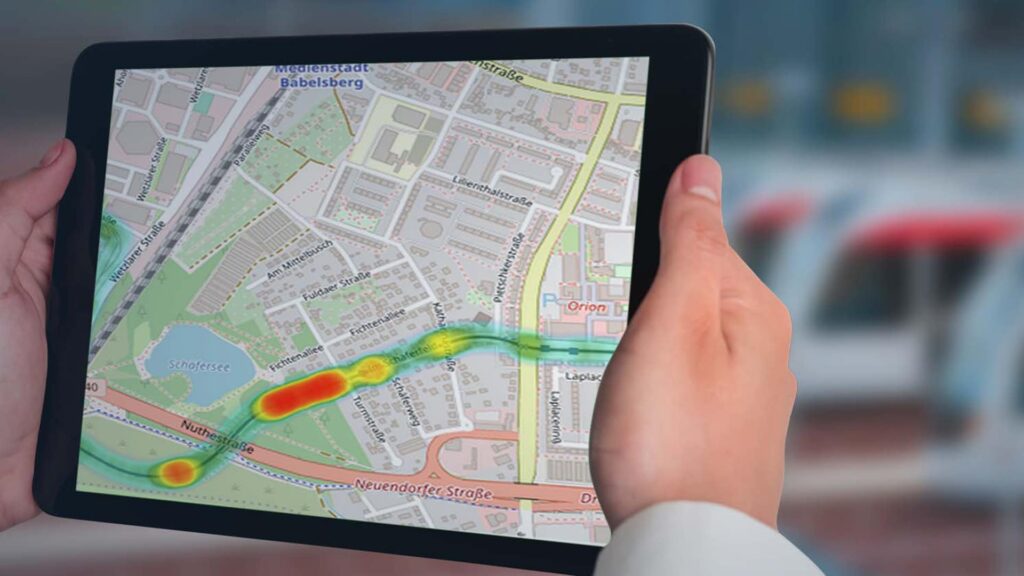

FOR SMART RAIL OPERATIONS

By monitoring “health states,” identifying optimization potentials in the network, and enabling predictive maintenance, our application development transforms your data into knowledge.

Subsystem integration for the vehicle control unit and operator network

SO IT ALL WORKS TOGETHER

When subsystem integration is performed for the vehicle control unit and operator network, we take full responsibility for combining multivendor architectures to form a functioning whole.

Innovations

WE’RE SHAPING THE FUTURE

We play an active role in both national and international research projects that are working to prepare rail vehicle technology for the challenges of future decades.

Development of a basic system

BASIS FOR THE FUTURE

By participating in international standardization projects, we’re contributing to the creation of a highly expandable and modular basic system of the future.

Device integration for SIMATIC PCS 7 / SIMATIC PCS neo

YOUR COMPONENTS IN A LEADING POSITION

Siemens’ SIMATIC PCS 7 and SIMATIC PCS neo control systems are leaders in the process industry. We take responsibility for a seamless, system-compliant integration of your products or third-party components.

PROFINET Stack Integration

WE HELP YOU MAKE IT TO THE BIG LEAGUES

You want to integrate PROFINET into your chips or devices – we handle the modification of the relevant stacks as part of a carefree package for you – right up to certification.

System integration for industrial communication

SO THAT NO DATA-POINT IS LOST

Whether it’s PROFINET, OPC UA, MQTT, or applications based on them, we take on the complete integration of products for industrial communication into your system environment.

Development of IoT and edge applications

DATA BECOMES THE BASIS FOR DECISION-MAKING

You want to turn big data into smart data. We’ll build your application – from data acquisition (connectivity) and data transmission to data evaluation and utilization.

MINDSPHERE® EFFICIENCY SUITE

Would you like to move your entire production plant to the IoT cloud? Our specially developed MindSphere® Efficiency Suite can help. We use it to model and structure your plant in the cloud – efficiently, securely, and with much less effort than you’d expect.

IO-LINK LIBRARY FOR SIMATIC PCS 7/SIMATIC PCS NEO

Secure point-to-point connections in industry are relatively easy to implement with the right IO-Links. We offer you the right driver so that integration is in full compliance with the system.

TURCK Remote IO FOR SIMATIC PCS 7

The system-compliant connection of TURCK systems to the SIMATIC PCS 7 process control system doesn’t have to be time-consuming. Our function block library ensures maximum convenience at the user end.

Cyber security for component manufacturers

SECURE FROM THE START

How we help you eliminate potential vulnerabilities in your products – from product development throughout the entire lifecycle.

Cyber security for plant operators:

MORE PROTECTION FOR YOUR ASSETS

How we can help you monitor and mitigate risks during operation – supported by our combination of system, software, and security expertise.